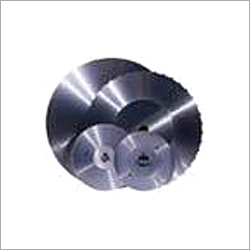

Food Processing Blades

Price 350 INR/ Piece

MOQ : 1 Piece

Food Processing Blades Specification

- Tool Type

- Industrial Blade

- Cutting Speed

- High

- Coating

- Uncoated

- Length

- Custom as per requirement

- Cutting Accuracy

- 0.1 mm

- Shape

- Flat, Circular

- Cutter Type

- Serrated, Plain Edge

- Features

- High corrosion resistance, Food-grade, Long lasting sharpness

- Machine Type

- Slicer, Dicer, Chopper

- Cutting Capacity

- Up to 10 mm thickness

- Operate Method

- Manual and Automatic

- Material

- Stainless Steel

- Cutting Force

- Low to Moderate

- Hardness

- 58-62 HRC

- Operation Type

- Semi-automatic, Fully Automatic

- Diameter

- 150 mm to 400 mm

- Processing Type

- Food Processing

- Temperature Tolerance

- Up to 250°C

- Blade Thickness

- 0.5 mm to 3 mm

- Edge Type

- Straight and Wavy

- Resharpening

- Yes, multiple cycles supported

- Packaging

- Secure PE bag and wooden box

- Application

- Used for cutting, dicing and slicing food products like vegetables, fruits, meat, and bakery items

- Blade Size

- 6 to 16 inches

- Surface Finish

- Polished

- Maintenance

- Easy to clean and maintain

- Hygiene Certification

- Meets FDA and EU standards

Food Processing Blades Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 5000 Pieces Per Week

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Food Processing Blades

Owing to our profound knowledge of this domain, we are able to provide remarkable Food Processing Blades in varied needs of the clients such as; from 3" to 20" in diameter. These are manufactured with the latest CNC grinding equipment in order to achieve up to 3 times longer blade life than those manufactured using files. Hence, we are appreciated as a reliable Manufacturer, Exporter, Importer, Wholesaler and Distributor of the arena. Apart from this, we also manufacture Food Processing Blades in time bound manner using ultra modern technology.

Versatile Cutting Performance

Engineered for superior precision, our blades are available in both straight and wavy edges, making them ideal for a diverse array of food productsranging from tough meats to delicate bakery items. Their compatibility with slicers, dicers, and choppers ensures efficiency across any operation size.

Durable, Food-Safe Materials

Manufactured using high-grade stainless steel, these blades resist corrosion and maintain sharpness through extended use. The polished finish and compliance with FDA and EU regulations guarantee maximum food safety and hygiene in demanding environments.

Customizable for Your Needs

Offering blade lengths between 6 to 16 inches and diameters of 150 mm to 400 mm, our blades can be tailored to match specific processing requirements. Custom options support both manual and automated processing setups, serving distributors, manufacturers, and suppliers throughout India.

FAQs of Food Processing Blades:

Q: How do I maintain and clean food processing blades to ensure hygiene and longevity?

A: To maintain optimal hygiene and extend blade life, clean blades immediately after use with mild detergent and warm water. Their polished, food-grade surface simplifies cleaning, reducing the risk of residue buildup. Regular inspection and adhering to proper resharpening cycles boost longevity and performance.Q: What benefits do straight and wavy edge types offer in food processing applications?

A: Straight edges provide clean, precise cuts suitable for slicing vegetables and fruits, while wavy (serrated) edges excel at dicing tougher products or slicing bakery items without compressing them. Choosing the appropriate edge boosts efficiency and preserves food quality.Q: When should I resharpen the blades, and how often can they be resharpened?

A: Resharpen the blades when you notice cutting performance decreasing, such as increased force needed or uneven slicing. Our blades are engineered for multiple resharpening cycles, maintaining high accuracy and sharpness over repeated uses.Q: Where are these blades suitable for use within the food processing industry?

A: These blades are suitable for use in processing facilities dealing with vegetables, fruits, meats, and bakery goods. Their versatility matches both semi-automatic and fully automatic machines like slicers, choppers, and dicers across industrial kitchens and manufacturing plants.Q: What is the process for sourcing and installing your blades in India?

A: Contact our distributor network or supply partners for customized blade options to suit your specific machine type. Blades arrive in secure PE bags and robust wooden boxes, ready for immediate installation by qualified technicians to ensure optimal fit and safety.Q: Can your blades handle high-speed operation and thick food products?

A: Yes, our blades are designed for high-speed cutting and can process food items up to 10 mm thick. Their hardness and structure allow for low to moderate cutting force while maintaining high accuracy and efficiency, suitable for demanding industrial workloads.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Circular Saw Blades Category

Friction Saw Blades

Price 350 INR / Piece

Minimum Order Quantity : 1 Piece

Cutting Capacity : Highly efficient for various thicknesses of structural and solid steel

Operate Method : Mechanical, suitable for industrial sawing machines

Coating Type : Uncoated

Material : Others, High grade chromevanadium steel

Send Inquiry

Send Inquiry